In today’s fast-paced world, where efficiency is the key to success, businesses are constantly searching for innovative ways to streamline their operations. One area that often goes unnoticed but holds immense potential for improvement is the packaging process. A vital component of this process is the pallet wrapping machine, a remarkable invention designed to enhance efficiency, reduce labor costs, and ensure the utmost safety in the transportation and storage of products.

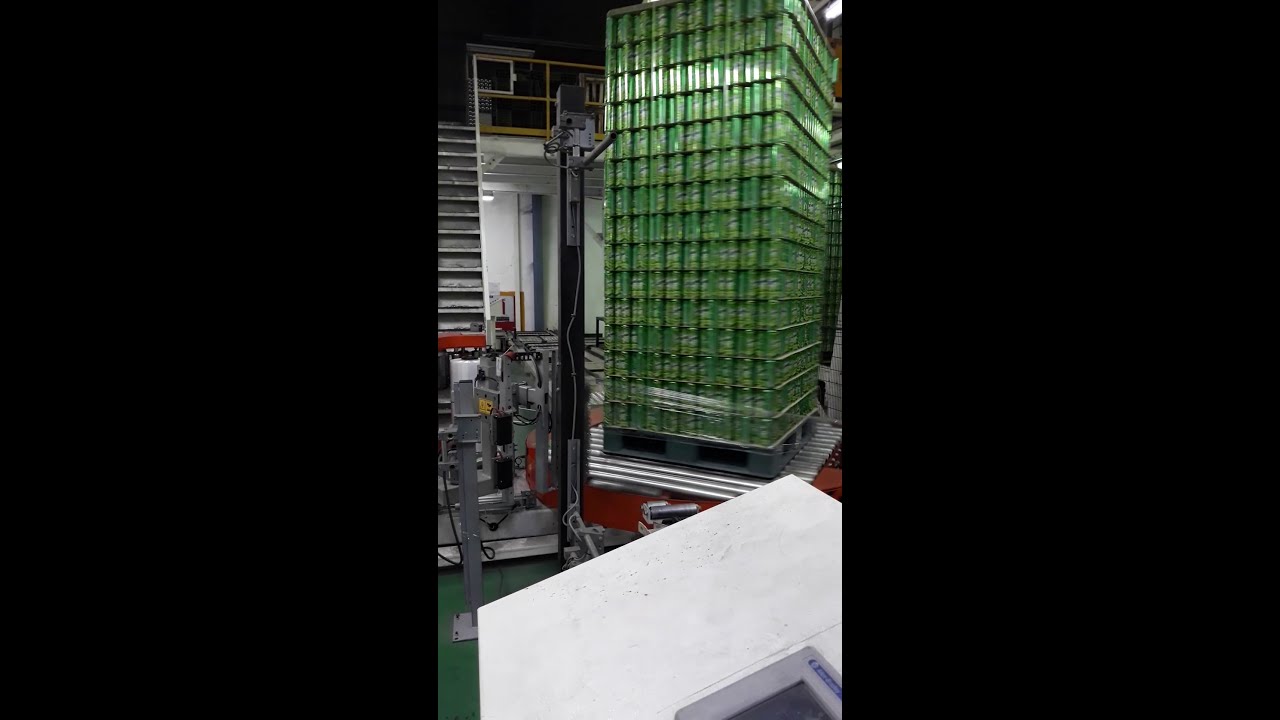

The pallet wrapping machine, also known as a pallet wrapper, stretch wapper, or stretch wrap machine, revolutionizes the packaging industry by automating the arduous task of wrapping pallets. This powerful machine utilizes stretch film to securely encase and protect a package, maintaining its integrity even in the face of demanding logistics operations. With its ability to firmly hold products together, pallet wrapping machines eliminate the risk of items shifting or toppling over during transit, minimizing potential damage and ensuring customer satisfaction.

By taking advantage of advanced technology and smart design, pallet wrapping machines enable businesses to achieve unparalleled levels of efficiency. These machines are equipped with adjustable settings, allowing users to customize the wrapping process according to the specific needs of their cargo. Whether it be choosing the appropriate tension level or setting the desired number of wraps, operators have complete control over the packaging process, ensuring optimal results every time.

Furthermore, the time-saving benefits of pallet wrapping machines cannot be overstated. Manual wrapping not only requires a significant amount of time but also increases the risk of repetitive strain injuries for employees. With a pallet wrapper, this labor-intensive task is completed in a fraction of the time, freeing up valuable resources that can be allocated to other crucial aspects of the business. Additionally, the sophisticated automation offered by these machines reduces the margin for error, guaranteeing consistent and reliable wrapping results.

In conclusion, the pallet wrapping machine is a game-changer for businesses striving to master efficiency in their packaging operations. With its ability to securely encase products, streamline processes, and save time, this powerful tool not only enhances productivity but also contributes to cost savings and improved customer satisfaction. By investing in a pallet wrapping machine, companies can unlock the true potential of their packaging process, setting the stage for success in an increasingly competitive market.

1. The Benefits of Pallet Wrapping Machines

Pallet Wrapping Machines, also known as Pallet Wrappers, Stretch Wrappers, or Stretch Wrap Machines, offer numerous benefits to businesses in various industries. These innovative machines have revolutionized the packaging and shipping process, providing increased efficiency and cost savings. In this section, we will explore some of the key advantages of using Pallet Wrapping Machines.

Improved Stability and Protection:

One of the primary benefits of Pallet Wrapping Machines is their ability to provide superior stability and protection to palletized loads. The machine uses stretch film to tightly secure the items onto the pallet, preventing movement and reducing the risk of damage during transportation. This enhanced stability ensures that products arrive at their destination in optimal condition, minimizing the potential for costly losses or returns.

Time and Labor Savings:

Traditionally, wrapping pallets by hand can be a time-consuming and labor-intensive task. Pallet Wrapping Machines automate this process, allowing businesses to wrap multiple pallets quickly and effortlessly. By eliminating the need for manual labor, these machines help companies save valuable time and reduce the physical strain on employees. This increased efficiency translates into higher productivity and lower operational costs.

Cost-Effective Solution:

Investing in a Pallet Wrapping Machine can result in significant cost savings for businesses. By using stretch film efficiently, these machines minimize the amount of film required per pallet, reducing material expenses. Additionally, the increased stability provided by the machine reduces the risk of product damage, further cutting down on losses and associated costs. Over time, the savings generated by Pallet Wrapping Machines can result in a substantial return on investment for companies of all sizes.

In conclusion, Pallet Wrapping Machines offer a range of benefits that streamline the packaging and shipping process. From improved stability and protection to time and labor savings, these machines are indeed a game-changer for businesses seeking enhanced efficiency and cost-effectiveness. By harnessing the power of Pallet Wrapping Machines, companies can optimize their operations and stay ahead in today’s competitive marketplace.

2. Choosing the Right Pallet Wrapping Machine

When it comes to maximizing efficiency in your packaging process, selecting the correct pallet wrapping machine is crucial. With the right machine, you can streamline operations and ensure that your products are securely wrapped and protected during transit. Here are some factors to consider when choosing a pallet wrapping machine.

Shrink Wrap Machine

Load Size and Weight: The first step in selecting the right pallet wrapping machine is to assess the size and weight of your loads. Different machines have varying load capacity limits, so it’s important to choose one that can handle the dimensions and weight of your pallets. This will ensure that the machine operates smoothly and avoids any potential damage or accidents.

Wrapping Requirements: Consider the specific requirements of your wrapping process. Do you need a machine that can wrap multiple layers of stretch film? Or perhaps you require a machine that can apply pre-stretched film for added cost savings. Understanding your wrapping needs will help you narrow down the options and select a machine that is tailored to your specific requirements.

Durability and Reliability: Look for a pallet wrapping machine that is built to withstand the demands of your packaging environment. It should be robust, durable, and capable of handling continuous operation without frequent breakdowns or maintenance. Investing in a reliable machine will minimize downtime and ensure that your packaging process remains efficient and uninterrupted.

By carefully considering these factors, you can choose the right pallet wrapping machine that aligns with your unique packaging needs. An efficient and reliable machine will not only save you time and effort but also contribute to the overall success of your business. Keep these considerations in mind as you explore the wide range of options available in the market.

3. Maximizing Efficiency with Pallet Wrapping Machines

Pallet wrapping machines, also known as pallet wrappers or stretch wrap machines, play a crucial role in streamlining operations and improving efficiency in warehouses and shipping facilities. These machines are designed to securely wrap pallets with stretch film, ensuring stability and protection during transportation and storage. By harnessing the power of pallet wrapping machines, businesses can maximize productivity and minimize waste.

One of the key advantages offered by pallet wrapping machines is their ability to automate the wrapping process. With manual wrapping, workers need to spend significant time and effort in carefully wrapping each pallet. This can be a labor-intensive and time-consuming task, particularly in facilities with high volumes of pallets. By using pallet wrapping machines, businesses can significantly reduce the time and manpower required for wrapping, allowing employees to focus on other important tasks.

In addition to saving time, pallet wrapping machines also ensure consistent and reliable wrapping results. These machines are equipped with advanced technology that guarantees uniform tension and film application, eliminating the risk of over-stretching or under-stretching the film. This consistent wrapping not only improves the overall appearance of pallets but also enhances load stability, reducing the possibility of product damage during transit.

Furthermore, pallet wrapping machines enable businesses to achieve optimal film usage. These machines are designed to stretch the film while wrapping, maximizing its length and minimizing waste. With manual wrapping, workers may tend to use excessive amounts of film, leading to unnecessary expenses and environmental impact. By utilizing pallet wrapping machines, companies can achieve cost savings by reducing film consumption and promoting sustainability in their packaging practices.

Recent Comments